This ITRC Technology Information Sheet provides basic information for using a fan to ventilate a crawlspace for mitigating vapor intrusion into the occupied space of a building. The design objective of CSV is to dilute crawlspace vapors to concentrations less than levels of concern. Controls on the location and volume of air removed from the crawlspace are needed to avoid significant heating or cooling impacts to the residents above the crawlspace. Consequently, CSV is typically used when other technologies are not feasible. Only experienced practitioners should provide services for this mitigation technology. |

Overview

Crawlspace ventilation mitigates vapor intrusion (VI) through dilution of VOC concentrations in crawlspace air. Ventilation of a crawlspace may be achieved by removing air from the crawlspace and replacing it with fresh air. As crawlspaces tend not to be sealed, and are usually connected to other parts of the basement and/or the occupied space above, CSV is more common than crawlspace depressurization because it may not be practical or desirable to remove enough air from a crawlspace to create a significantly depressurized space. CSV typically involves the opening of existing exterior vents, if present, around the crawlspace to provide a source of supply air. There are varying considerations for design and implementation of CSV depending on whether the crawlspace is accessible (from inside the building or from outside) or inaccessible. CSV may be more challenging to implement in an inaccessible crawlspace. When the crawlspace is accessible crawlspace sub-membrane depressurization may be a better option than CSV.

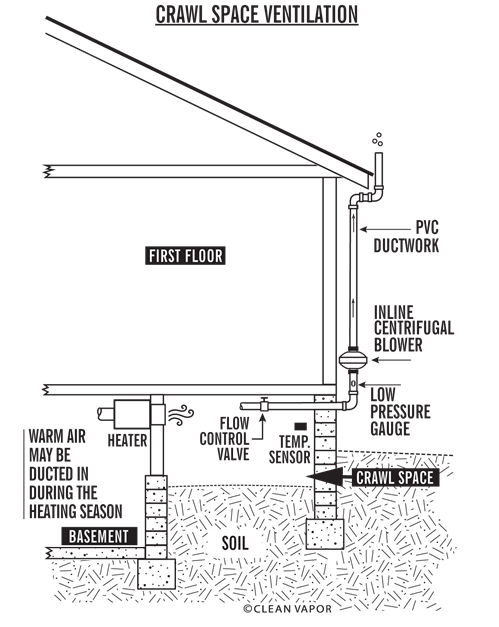

Source: Clean Vapor, LLC, used with permission.

CSV design should achieve the movement of the minimum amount of air out of the crawlspace to create a modest, but consistent, air exchange rate (AER) for the space that is sufficient to dilute crawlspace vapor concentrations to below levels of concern. The AER may vary, but a typical range is between 1 and 3 air exchanges per hour. Additionally, sealing of openings in the floor separating the crawlspace from the above occupied space should be considered to minimize the volume of indoor air drawn across the floor and into the crawlspace prior to the atmospheric discharge through the CSV process. Sealing of cracks/openings between the crawlspace and the occupied space can minimize additional energy costs when building air is heated or cooled.

The CSV design should also explicitly avoid the risk of back drafting combustion appliances. Back drafting may occur if combustion gases are prevented from atmospherically venting and instead are drawn into building and/or crawlspace air spaces, thereby creating unsafe conditions. National consensus standards, such as those published by the American Association of Radon Scientists and Technologists/American National Standards Institute (AARST/ANSI), and applicable national and local building codes should be consulted with regards to back drafting requirements.

Depending on the size of the crawlspace, several methods can be used for ventilation. One method involves installing solid piping into the crawlspace, sealing the annular space around the piping penetration, and extending the piping to an exterior-mounted fan that discharges ventilated air above the roofline and away from building openings. Alternatively, smaller crawlspaces with existing exterior vent openings may be adequately vented using a crawlspace ventilator fan. See Figure 1 for an example CSV system configuration.

For new buildings in areas with VI potential, it is preferable to mitigate vapors in a crawlspace using sub-membrane depressurization (SMD) systems rather than CSV because the combination of depressurization and a barrier can typically be engineered to provide for a more effective mitigation solution. See the ITRC Sub-Membrane Depressurization Technology Information Sheet for more information.

Components

This technology requires a fan or blower connected via piping to the crawlspace. See Figure 1 for an example photo of piping exiting a crawlspace. Other features of a CSV include:

- system piping, including a sampling port for accessing system air velocity/flow data and for obtaining effluent samples to quantify chemical concentrations, if needed. These data may be used to estimate chemical mass flux in vented crawlspace air.

- valves or other means for adjusting the airflow. This may be achieved by installing a flow control valve or fan motor speed controller, or through sizing of the piping and fan.

- instrumentation (either permanent or included during operations, maintenance, and monitoring (OM&M) visits) to measure pressure differentials between the crawlspace and adjacent occupiable spaces.

Heating season contaminant of concern concentrations in the crawlspace should be known and targeted AER and pressure differential values between the crawlspace and surrounding occupiable space should be established as part of the design and implementation process. There will be a variable seasonal relationship between pressure differential values and the volume of air exhausted from the crawlspace. In cold climates, design considerations should also include utility insulating, temperature monitoring, heat tracing of pipes, and ducted warm air that is thermostatically actuated to keep pipes from freezing. Freezing of condensation in ventilation pipes or non-CSV-related utilities that contain water may be of potential concern.

Source: C. Regan, ERM, used with permission.

Advantages

CSV has the following advantages:

- This is a readily deployable engineering control.

- CSV works in crawlspaces with limited accessibility.

- It is possible to monitor performance using metrics that are readily measurable (i.e., airflow rates).

- A CSV system can easily be connected to remote monitoring and control technologies.

Limitations

CSV has the following limitations:

- Installation and OM&M may require confined space training depending on crawlspace construction and if entry is needed.

- A thorough health and safety evaluation should be completed, and potential hazards addressed prior to entering a crawlspace. In some cases, crawlspace entry may not be necessary or possible. All applicable protocols for confined space entry must be followed for crawlspaces.

- Potential impacts to occupants of the building being mitigated from operation of the CSV ventilation system should be considered, including the potential for heat loss in the livable space above the crawlspace or the potential for increased energy costs from operating the system.

- The presence of asbestos in the crawlspace may require removal or abatement prior to CSV installation and activation. In certain circumstances, the presence of asbestos may eliminate CSV as a mitigation strategy.

- CSV may not be used if atmospherically vented combustion appliances are present within the crawlspace.

- A high energy penalty may be incurred due to the potential for removal of conditioned air from the building space above the crawlspace.

- Extensive sealing may be required between the crawlspace and basement (if present) and the crawlspace and building space above the crawlspace to isolate the crawlspace.

- In cold climates, design considerations should include measures to keep pipes from freezing, as described above.

Cost Considerations

The primary factors that affect the overall cost of a CSV system include:

- the presence of heating/cooling ductwork

- water piping

- size of the building (indirectly as it relates to crawlspace size and length of pipes needed)

- size of the crawlspace

- tightness of the floor between the crawlspace and the overlying occupied space

- presence of exterior vents

- remote monitoring

- OM&M requirements

The approximate costs for installation of this technology range from $2 to $4 per square foot of crawlspace These costs are typically for installation only and do not necessarily include the costs of predesign testing; preparation of a work plan, design and specifications; installation monitoring; regulatory agency and stakeholder liaising; post-installation verification testing; and reporting.

Cost factors include but are not limited to the following:

- size of the crawlspace

- system components

- climate and need for insulation

- means of controlling and monitoring the system’s performance

Energy cost for CSV systems can be calculated by understanding the power draw of the blower, the building energy demand based on climate (i.e., the heating degree days) to estimate heat loss, and the local costs for power.

Special Circumstances

Special circumstances for construction of a CSV include:

- CSV should be considered when SMD is not practical due to lack of access to the crawlspace (typically shallow crawlspaces).

- Installation of warning placards may be appropriate at the entrance to the crawlspace to notify entrants of the possible presence of vapors within the crawlspace and of the importance of maintaining a sealed crawlspace entrance.

- Designs should avoid excess air removal from crawlspaces to protect against the potential for back drafting, minimize the potential for freezing of pipes located within the crawlspace, and minimize increases in heating/cooling costs.

- CSV typically requires opening of exterior crawlspace vents when present.

- To the extent possible, a barrier should be placed across the ground surface of the crawlspace, even if the barrier cannot be fully sealed or the entire crawlspace extent accessed.

- Instrumentation and equipment to regulate and measure air flow rates to achieve a targeted ventilation rate should be conducted by an individual who is experienced in this practice.

- In cold climates, temperatures should be monitored so actions can be taken to avoid freezing pipes.

Occupant, Community, and Stakeholder Considerations

It is essential to develop and implement a site-specific community involvement plan that addresses how to win trust and gain access to properties, communicate risk to potentially exposed individuals, and minimize the disruption of people’s lives and businesses. For more details see ITRC’s Public Outreach during Vapor Intrusion Mitigation Fact Sheet.

References and Resources

- ITRC Technical and Regulatory Guidance Document, Vapor Intrusion – A Practical Guideline, 2007.

- ITRC Petroleum Vapor Intrusion, Fundamentals of Screening, Investigation and Management, 2014.

- Soil Gas Mitigation Standards for Existing Homes, 2017, AARST Consortium on National Radon Standards, ANSI/AARST SGM-SF 2017.

Related Links:

For more information and useful links about VI pathways and mitigation technologies, go to http://www.itrcweb.org/ .

[email protected], 919-707-8279 Matthew Williams, Michigan Dept. of Environment, Great Lakes, and Energy [email protected], 517-881-8641 |

Click here to view a PDF version of this Tech Sheet.