1 Introduction

The Interstate Technology and Regulatory Council (ITRC) has developed nine fact sheets and one additional technology information sheet for emerging technology to summarize the latest science, practices, and new approaches for vapor intrusion (VI) mitigation. The fact sheets are intended to address needs of regulatory program personnel regarding sites with known or potential VI impacts. The content is also useful to practitioners (i.e., environmental consultants or engineers) and parties responsible for the release of these contaminants, as well as public and tribal stakeholders. The fact sheets in the series are:

| Emergency (911) Situations This document does not cover emergency response actions related to VI creating a combustible, explosive, or other hazardous environment. If strong odors are detected or there is reason to believe that combustible, explosive, oxygen-deficient, or toxic condition exists inside a building, immediately evacuate the building and contact first responders. |

Overarching VI Mitigation Topics

1. Conceptual Site Models (CSM) for Vapor Intrusion Mitigation

2. Public Outreach During Vapor Intrusion Mitigation

VI Mitigation Considerations

3. Design Considerations

4. Post-Installation Considerations

5. Operations, Maintenance, and Monitoring (OM&M) Considerations

VI Mitigation Strategies

6. Rapid Response and Ventilation

7. Active Mitigation Systems

8. Passive Mitigation Systems

9. Remediation and Institutional Controls

Technology Information Sheet for Emerging Technology

10. Aerobic Vapor Mitigation Barrier (AVMB)

This document includes a brief introduction to VI; however, it is assumed that the user has previous knowledge of VI topics, especially related to evaluation of the VI pathway and VI sampling. Knowledge of VI topics provides the foundation to understand the requirements, implementation, and verification of an adequate VI mitigation strategy that protects public health. Therefore, it is highly recommended that users of this document refer to the following references for additional background information regarding VI:

- ITRC – Petroleum Vapor Intrusion: Fundamentals of Screening, Investigation, and Management (ITRC, 2014)

- ITRC – Vapor Intrusion Pathway: A Practical Guideline (ITRC, 2007a)

- U.S. Department of Defense – DOD Vapor Intrusion Handbook (USDOD, 2009)

- U.S. Environmental Protection Agency (USEPA) – Technical Guide for Addressing Petroleum Vapor Intrusion at Leaking Underground Storage Tank Sites, Office of Underground Storage Tanks (USEPA, 2015a)

- USEPA – Technical Guide for Assessing and Mitigating the Vapor Intrusion Pathway from Subsurface Vapor Sources to Indoor Air, Office of Solid Waste and Emergency Response (USEPA, 2015b)

1.1 What is Vapor Intrusion?

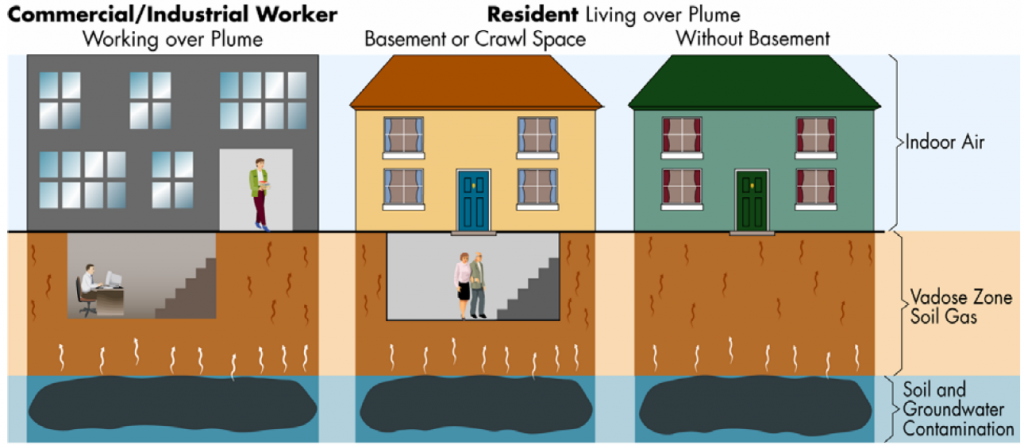

Chemical contaminants in soil and groundwater can volatilize into soil gas and migrate through unsaturated soils of the vadose zone. VI occurs when these vapors migrate upward into overlying buildings through cracks and gaps in the building floors, foundations, and preferential pathways (e.g., utility conduits, sewer lines) and contaminate indoor air (see also Conceptual Site Models for Vapor Intrusion Mitigation Fact Sheet). If present at sufficiently high concentrations, these vapors may present a threat to the health and safety of building occupants. VI is a potential human exposure pathway—a way that people may come into contact with hazardous vapors while performing their day-to-day indoor activities (USEPA, 2015b).

|

VI chemicals of concern (COCs) vary by regulatory agency and may include:

- volatile organic compounds (VOCs) such as hydrocarbons (for example benzene), chlorinated hydrocarbons (for example trichloroethylene (TCE), tetrachloroethylene (PCE), and vinyl chloride), and methane

- select semi-volatile organic compounds such as some polycyclic aromatic hydrocarbons (PAHs), naphthalene, and some polychlorinated biphenyls (PCBs)

- select inorganic compounds, such as mercury (elemental), pesticides, and hydrogen cyanide

- per- and polyfluoroalkyl substances (PFAS)

Note that background COC contributions to indoor air unrelated to the subsurface may complicate interpretation of indoor air sampling results, such that additional lines of evidence should be considered when generating a site CSM (see also Conceptual Site Models for Vapor Intrusion Mitigation Fact Sheet) or evaluating performance of selected VI mitigation strategies. Conceptual site models for VI are typically developed and modified throughout the investigative process. Examples of generalized VI scenarios that a CSM would be developed for are illustrated in Figure 1-1.

Figure 1-1: Generalized VI scenarios (from ITRC 2007 VI Guidance, Figure 1-1).

1.2 What is the Objective of VI Mitigation?

The objective of VI mitigation is to reduce indoor air COCs due to VI below applicable action or screening levels. This requires modification of the VI pathway to reduce the mass flux of COCs entering the building and/or to reduce indoor air COC concentrations by removal or dilution. Sections 2, 3, and 4 below introduce the user to the fact sheets and what to expect from each document.

As illustrated in the Conceptual Site Models for Vapor Intrusion Mitigation Fact Sheet figure titled “Flowchart for Vapor Intrusion Mitigation Conceptual Site Model Development.” mitigation technologies can be applied at different points along the VI pathway to accomplish these goals. Understanding how a mitigation technology is modifying the VI pathway helps us understand 1) whether the technology is compatible with the site conditions and stakeholder objectives (e.g., cost, timeliness, sustainability, etc.), and 2) what information is needed to evaluate the performance of the system over the short and long terms.

Examples of common mitigation technologies applied below the slab[1] (e.g., sub-slab technologies), at the slab (e.g., vapor barriers), and inside the building (e.g., heating, ventilation, and air conditioning [HVAC] controls) are described below, including how they modify the VI pathway and information typically needed to evaluate the suitability and performance of the technology at a site. A similar thought process should be applied to other mitigation technologies that are not discussed below but may be considered at a site, such as technologies to address COC migration into buildings through preferential pathways (e.g., sewer lines or utility tunnels). Refer to the Preferential Pathway Sealing and Ad Hoc Ventilation Technology Information Sheet. See the ITRC VI mitigation technology information sheets included with each VI mitigation approach fact sheet for more detailed information, including recommendations for design and implementation of specific technologies.

Radon Mitigation Systems Are Not Necessarily VI Mitigation Systems

|

In certain instances, radon mitigation providers do not understand how VI is different from radon mitigation and are not installing systems that provide the level of coverage necessary for regulatory acceptance and public health protectiveness. Additionally, many radon mitigation providers do not have the training/experience to design VI mitigation systems for large buildings, such as determining if exhaust controls are required and having licenses to obtain necessary building permits.

Pre-emptive VI mitigation is common for new construction and is defined as designing and implementing VI mitigation measures without a requirement or without confirmation that an unacceptable risk is or would be present. While an institutional control (e.g., land use restriction) may be in place for a site that requires VI mitigation for new construction (such as when constructing on an undeveloped site with known contamination), pre-emptive mitigation is commonly selected even when VI impacts do not warrant VI mitigation. Pre-emptive VI mitigation can limit concern that may be related to migration of COCs associated with an existing release or a future release and in some cases, can increase building value.

[1] Vapor intrusion can occur through any subsurface portion of the building shell, including floor slabs, foundation walls, elevator shafts, sumps and vaults, and any other building component in contact with the ground, including bare soil in basements or crawl spaces. For simplicity, however, we will use the term “slab” in this fact sheet to represent the building/subsurface interface through which vapors can migrate.

1.3 How to Use This Document

This document provides regulators, practitioners (i.e., environmental consultants or engineers), and parties responsible for the release of these contaminants, as well as public and tribal stakeholders, with consensus information based on data, research, and experience gained from case studies, to support VI mitigation decision making under different regulatory frameworks. Further, this document is meant to assist regulators in reviewing or determining appropriate VI mitigation strategies and to help practitioners appropriately design and implement VI mitigation strategies.

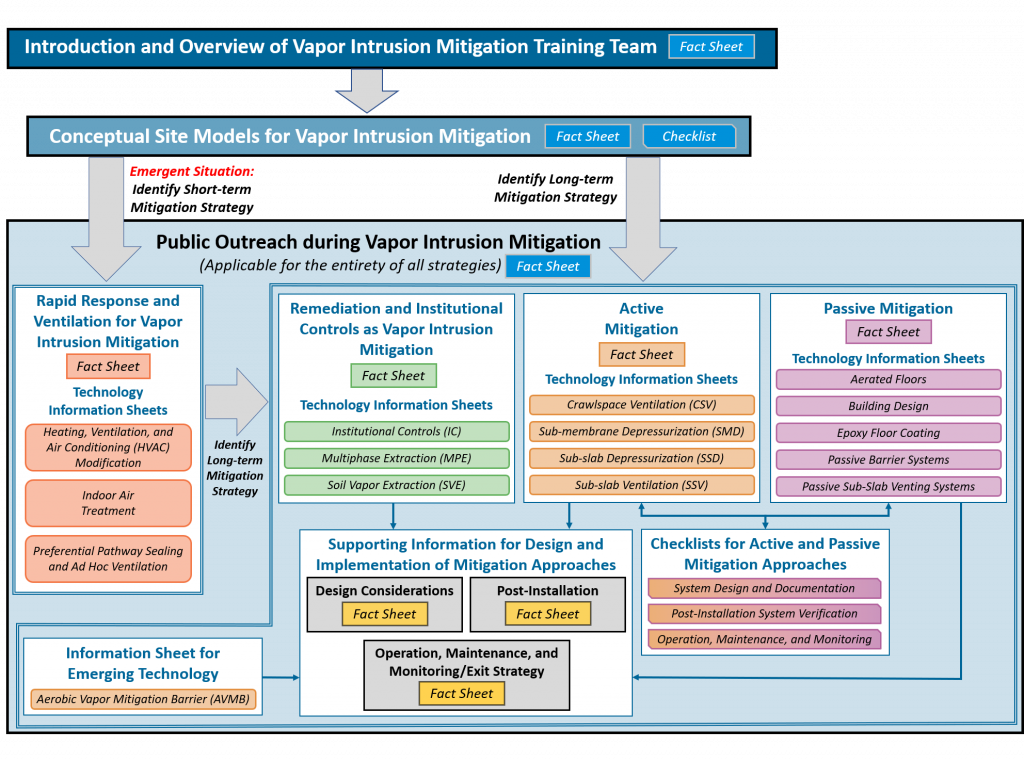

Figure 1-2 is a graphical depiction of the organization of the fact sheets, technology information sheets, and checklists prepared in support of VI mitigation training.

Figure 1-2 Document map for work products prepared by the VI mitigation training team.

Generally, a regulator or practitioner should approach each site by following the step-wise approach outlined in this document by navigating from the materials introduced in Section 2 (Overarching VI Mitigation Topics) and using the Conceptual Site Models for Vapor Intrusion Mitigation Fact Sheet as guidance for which fact sheets in Section 3 (VI Mitigation Considerations) and Section 4 (VI Mitigation Strategies) are applicable. It’s important to note that topics detailed in the Public Outreach During Vapor Intrusion Mitigation Fact Sheet should be followed at every step in the VI mitigation process—from initial site characterization to follow-up and maintenance for the life of the building.

2 Overview of Overarching VI mitigation TOPICS Fact sheets

Two fact sheets, Conceptual Site Models for Vapor Intrusion Mitigation and Public Outreach During Vapor Intrusion Mitigation provide information that is relevant throughout the entire mitigation effort. A brief overview of each fact sheet is found below.

2.1 Conceptual Site Models for Vapor Intrusion Fact Sheet

The Conceptual Site Models for Vapor Intrusion Mitigation Fact Sheet provides a general overview of the VI pathway, including the locations and types of vapor sources, subsurface vapor transport mechanisms, foundation and other building conditions affecting the rate of vapor entry, and receptors that could be impacted by VI. The VI Mitigation CSM helps the practitioner evaluate the potential for a complete VI pathway, identify data gaps, and communicate findings and conclusions to other stakeholders.

This fact sheet introduces two tools to help focus the VI Mitigation CSM. The first is a checklist to help guide mitigation planning, and the second is a conceptual flowchart illustrating various VI pathways and strategies that could be employed to control these pathways. VI Mitigation CSMs that use this checklist and flowchart should allow more thorough identification of the specific VI pathways relevant to the site, as well as options for vapor control strategies.

2.2 Public Outreach During Vapor Intrusion Mitigation Fact Sheet

The Public Outreach During Vapor Intrusion Mitigation Fact Sheet details the importance and procedure for engaging the public at environmental contamination sites with VI concerns, specifically with the people who own; live, work, or study in; and otherwise occupy the impacted buildings. Their cooperation, not just permission, makes it possible to investigate, remediate, mitigate, and monitor at properties where COCs may be present. Regulators and practitioners may be asking them to agree to allow intrusive activities, such as drilling holes through their floors, attaching fans and piping to their buildings, or rearranging their basements for investigation or mitigation.

Topics covered in this fact sheet include characterizing community concerns, unique topics for the community involvement plan, and logistical considerations for the community involvement plan specifically pertaining to VI concerns. The user of this document should refer to the ITRC Risk Communications Plan Toolkit (ITRC, 2020) for generic guidance on developing a community involvement plan.

3 Overview of VI Mitigation considerations fact sheets

Three fact sheets for VI mitigation considerations includes design considerations, post-installation considerations, and operation, maintenance, and monitoring (OM&M) considerations. A brief overview of each fact sheet is found below.

3.1 VI Mitigation Design Considerations Fact Sheet

Prior to designing a mitigation system, it is common to perform a building survey and predesign diagnostic testing to understand specific issues that will need to be incorporated into any mitigation system design for either an active system (see Active Mitigation Fact Sheet), passive system (see Passive Mitigation Fact Sheet), or an environmental remediation technology that will be used as a mitigation strategy (see Remediation and Institutional Controls as Vapor Intrusion Mitigation Fact Sheet). Design considerations detailed in the fact sheet include geology and/or hydrogeology, building survey, new or existing building characteristics, design testing (qualitative verification), permitting, communications, long-term system effectiveness and reliability, operation and maintenance, and exit strategy.

3.2 VI Mitigation Post-Installation Fact Sheet

After the installation of an active (see Active Mitigation Fact Sheet) or passive (see Passive Mitigation Fact Sheet) mitigation system, or implementation of an environmental remedial technology (see Remediation and Institutional Controls as Vapor Intrusion Mitigation Fact Sheet), post-installation verification and testing for confirmation of the design and operating parameters is often required. It is during this time that the system is confirmed to be operating and meeting performance specifications.

3.3 VI Mitigation Operation, Maintenance, and Monitoring (OM&M)/Exit Strategy Fact Sheet

After a mitigation strategy that addresses an active (see Active Mitigation Fact Sheet) system, passive (see Passive Mitigation Fact Sheet) system, or an environmental remedial technology (see Remediation and Institutional Controls as Vapor Intrusion Mitigation Fact Sheet) has been designed and implemented, the OM&M (see Operation, Maintenance, and Monitoring/Exit Strategy Fact Sheet) of the selected mitigation strategy is critical to ensure long-term effectiveness of the system and protection of public health. Complex mitigation strategies will typically require more complex OM&M procedures. The key to any OM&M is to ensure that the system is operating as designed and that it remains effective in the long-term and until it is appropriate to implement an exit strategy.

4 Overview of VI Mitigation strategies fact sheets

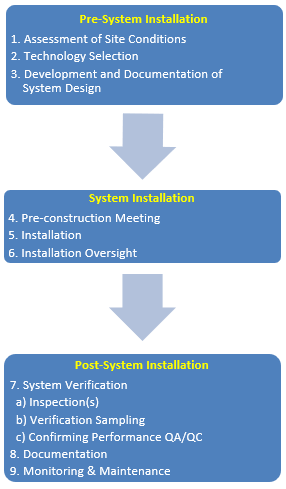

The four fact sheets for VI mitigation strategies include rapid response and ventilation, active mitigation measures, passive mitigation measures, and remediation and institutional controls. In general, VI mitigation strategies follow the process flow step diagram, Figure 4-1, noted on this page. A brief overview of each fact sheet is found below.

4.1 VI Mitigation Rapid Response and Ventilation Fact Sheet

Rapid response is an interim VI mitigation approach that may be appropriate, under certain conditions, prior to implementing a long-term mitigation strategy for an occupied room or building. For the purposes of this document, a rapid response is one that could be easily implemented and verified on a timescale of days to weeks and operated on a short-term basis while more immediate mitigation strategies are implemented. A long-term mitigation strategy will take longer to design, implement, and verify and is intended to operate until the remedial objectives are met. Note that some technologies or mitigation methods characterized in this document as rapid response may also be suitable as long-term mitigation strategies.

For cases where COCs are detected in indoor air at concentrations exceeding short-term exposure criteria, a rapid response is typically warranted. Rapid response actions may also include administrative controls, such as evacuating and eliminating occupant access to the building, or engineering controls that reduce chemical vapor exposure through building ventilation, indoor air treatment, or physically preventing vapor entry into the building.

4.1.1 HVAC and Indoor Air Mitigation Technologies

HVAC adjustments and air purifying units (APUs) are common techniques that can be used to address the presence of COCs in indoor air. Both can be used as rapid response actions to lower indoor air concentrations within a relatively short time frame (i.e., days). Note that neither technique is intended to remediate the VI source.

4.1.2 How HVAC and Indoor Air Mitigation Technologies Work

For buildings equipped with an engineered HVAC system, VI mitigation may be accomplished using HVAC as an engineering control. VI mitigation may be achieved by pressurizing the building—thereby controlling cross-slab pressures and preventing VI—and/or increasing air exchange rates by providing sufficient outdoor air exchange to dilute the effects of VI on indoor air quality.

APUs—commonly adsorption-based units that use a particulate filter and granular activated carbon—can be ducted onto the HVAC system or used as stand-alone, portable or wall-mounted units. APUs are intended to actively circulate indoor air and remove certain COCs present in the air stream.

4.1.3 How to Evaluate Performance

Performance evaluation for both techniques includes their ability to achieve acceptable indoor air concentrations under practical operating conditions and costs. Overall performance is subject to uncertainty, and follow-up indoor air sampling is necessary. Note that background COC contributions to indoor air unrelated to the subsurface may complicate interpretation of indoor air sampling results, such that additional lines of evidence, including differential pressure, airflow, and tracer gases, should also be considered when evaluating performance.

Potential concerns associated with HVAC adjustments include energy intensiveness and technical limitations (e.g., outdoor air is too humid). However, certain buildings with complex layouts or utility networks may achieve indoor air targets through adjustments to their HVAC with less disruption or expense than sub-slab depressurization (SSD) or sub-slab ventilation (SSV) installation, even when long-term operating costs are considered. HVAC adjustments and APUs may also provide temporary VI mitigation prior to installation of other mitigation systems. HVAC adjustments may also augment the performance of other mitigation systems (e.g., reduce SSD operating requirements).

Multiple factors need to be taken into consideration when selecting and sizing APUs (e.g., number of units and individual capacity). The total APU system airflow should be several times the baseline airflow through the space to be treated (e.g., 5–10 air exchanges per hour). COC mass loading and carbon consumption should also be considered. Potential limitations include competition from nontarget COCs (e.g., background sources), moisture, noise, and human interference.

4.2 Active Mitigation Fact Sheet

Active mitigation technologies are typically applied below the building slab. The most common approaches involve extraction of vapors from the subsurface materials (e.g., soil or gravel) immediately below the structure. Sub-slab depressurization (SSD)[2] and sub-slab ventilation (SSV) are the most commonly installed types. Other approaches detailed in the active mitigation measures fact sheet include sub-membrane depressurization (SMD) and crawlspace ventilation (CSV).

[2] Related approaches include sub-membrane depressurization, drain-tile depressurization, and block-wall depressurization.

4.2.1 How SSD and SSV Systems Work

SSD uses an electric fan to create a pressure gradient across the building envelope to prevent vapors from migrating from the subsurface into the building through soil gas advection. When a negative pressure differential is present below a building envelope relative to inside the building envelope, any communication between indoor air and the sub-slab soil gas (e.g., through cracks or improperly sealed utilities, etc.) will be one-way, from indoor air to below the slab, mitigating indoor air impacts. The goal for SSV is to reduce vapor concentrations below the floor of a structure’s slab to levels that are low enough to maintain acceptable indoor air concentrations above the slab, regardless of whether there is a consistent or even measurable vacuum below the floor. Because SSD and SSV systems both apply negative pressures and induce air flow below the slab, some dilution of COC concentrations and some reduction in upward air flow may occur with both approaches.

In some cases, SSV-type systems may be intended to help maintain oxygen levels below the building (usually at some depth below the building slab) and promote aerobic biodegradation of petroleum hydrocarbons, methane, and other compounds that tend to degrade aerobically in the vadose zone (e.g., vinyl chloride).

Active mitigation is chosen because, although natural forces (e.g., thermal gradients or wind) can induce negative air pressures and air flow below a slab (i.e., passive systems), these forces are generally weaker and much more variable than the pressures and air flows that can be induced by electric fans. While it may be reasonable in some situations to initially operate an installed SSD or SSV system in passive mode, adequate performance should be demonstrated and monitored, and the design should include a contingency for active operation if necessary. Typically, a system designed to operate passively have a different layout than a system designed and intended to operate as an active system.

4.2.2 How to Evaluate Performance

The initial and then continued long-term performance of an active mitigation system is reflected by collecting additional lines of evidence. These lines of evidence include readings from the system (e.g., air flow rate, vacuum, etc.) and how the system is affecting the building (e.g., differential pressure field extension under the slab, indoor air samples, etc.). System performance data are collected both during system commissioning and then periodically during system operation. Frequency of collecting performance data is determined on a site-specific basis. Data can be used both to verify system performance and to understand when a system may no longer be necessary and steps toward evaluating system decommissioning can be taken.

The performance of any mitigation system is ultimately reflected by indoor air concentrations of the COCs over time; however, interpretation of indoor air test results can be confounded by background sources and temporal variability. Therefore, additional and alternate ways to evaluate and monitor system performance can be valuable. SSD system performance is directly related to negative pressures, which can be continually monitored at relatively low cost. SSV system performance can be inferred by sub-slab vapor concentrations that are below screening levels (based on generic or site-specific attenuation factors); higher levels do not necessarily mean that indoor air is impacted, as screening levels are typically conservative, but also do not provide confirmation on their own that the system is performing adequately.[3]

[3] Combined with contemporaneous indoor air data, sub-slab vapor concentrations could potentially be used to develop or modify site-specific sub-slab attenuation factors.

4.3 Passive Mitigation Fact Sheet

Passive mitigation technologies are primarily intended to modify the VI pathway without the use of electrical or mechanical means and commonly involve creating a barrier to vapor migration through the slab, such as barriers placed immediately below slabs (new construction), sealing of cracks and other openings in slabs, and surface coatings. Common passive mitigation barrier systems detailed in the fact sheet includes asphalt latex membranes (ALM), thermoplastic membranes (TM), composite membranes (CM), and epoxy floor coatings (EFC). Other passive mitigation measures detailed in the fact sheet include passive venting systems, such as passive sub-slab venting and aerated floor systems (AFS), and building design specifications, such as raised foundations or vented garages.

4.3.1 Passive Barriers

In most cases, advective flux of COCs across the slab is the dominant transport mechanism of concern. Vapor barriers work by blocking the flow of soil vapor through joints, cracks, or other openings in the slab. Therefore, the quality of the seal between the vapor barrier and foundation and at penetrations through the slab will be most important. In some cases, sub-slab vapor concentrations are high enough for diffusion through the slab to be of concern. In these cases, vapor barriers work by reducing diffusion flux through the slab and the permeance of the barrier to the COCs is important.

Vapor barriers are typically included in the design of SSD systems for new construction, in part to limit the downward flow of building air through the slab, thus decreasing the size and/or number of fans required to depressurize the slab. The vapor barrier also reduces the potential for advective transport of COCs into the building if the fans temporarily shut down. Reduced sub-slab vapor COC concentrations due to sub-slab venting associated with SSD system operation also provide additional protection.

It should be noted that a successful barrier may cause COC concentrations to increase below the slab, unless otherwise controlled (e.g., by venting). This could be of concern if COCs diffuse laterally to other areas, or if future imperfections in the barrier allow sub-slab vapors to enter the building. Passive venting systems are often used in combination with passive barrier systems to prevent these conditions from occurring.

4.3.2 How to Evaluate Performance

As indicated above, the performance of any mitigation system is ultimately reflected by indoor air concentrations of the COCs over time. The integrity of the barrier can be evaluated by vacuum and/or smoke testing after construction, although this provides only a qualitative assessment of performance. Measurement of sub-slab vapor COC concentrations may suffice, if concentrations are below screening levels, although this may be unlikely with passive systems. Therefore, indoor air testing may be necessary in many cases to confirm performance of mitigation systems relying solely on vapor barriers.

4.4 Remediation and Institutional Controls as Vapor Intrusion Mitigation Fact Sheet

In some instances, environmental remediation technologies can serve as VI mitigation. Remedial technologies detailed in the fact sheet include soil vapor extraction (SVE) and multiphase extraction (MPE). Institutional controls can also provide protection and serve as an administrative assurance for mitigation of a known or potential VI concern.

4.4.1 Remediation Technologies for VI Mitigation

For remediation technologies to serve dually as VI mitigation and site cleanup, they must accomplish the same objective as a dedicated VI mitigation system, which is to reduce concentrations of the COCs in indoor air below the applicable regulatory levels. Remediation technologies that can serve that purpose include SVE and MPE. An overview of each of these technologies is detailed in the Remediation and Institutional Controls as Vapor Intrusion Mitigation Fact Sheet and accompanying technical information sheets. In general, the most common remedial technologies used for VI mitigation include SVE and MPE.

4.4.2 How to Evaluate Performance of Remediation Technologies for VI Mitigation

Similar to performance evaluation for active and passive mitigation measures above, remedial technologies used to address VI are reflected by indoor air concentrations of COCs over time. Measurement of sub-slab vapor COC concentrations over time provides evidence of the effectiveness of the remedial technology approach for VI mitigation.

4.4.3 Institutional Controls (ICs)

ICs are a form of land use controls (LUCs) that provide protection from exposure to site-related contaminants. While ICs consist of administrative or legal restrictions on a site, LUCs can also use physical measures, which are called engineering controls or ECs (e.g., physical barriers). In contrast to ECs, ICs are primarily government controls, proprietary controls, enforcement or permit mechanisms, and informational devices. Planning that protects human health and the environment and uses all aspects of an IC life cycle (ITRC, 2016) is essential for long-term success (e.g., a long-term stewardship plan). As it relates to the VI pathway, ICs can be applied as a stand-alone remedy (for undeveloped lands or restricted use on developed land), as part of an overall remedy selection, or as a permit that requires ongoing monitoring and maintenance of the mitigation system. More details are provided in the Institutional Controls Technology Information Sheet.

4.5 Technology Information Sheet for Emerging Technologies—Aerobic Vapor Mitigation Barrier (AVMB)

The Aerobic Vapor Mitigation Barrier Technology Information Sheet describes a method for in situ VI mitigation and remediation at sites with existing buildings situated above subsurface sources of VOCs that rapidly biodegrade aerobically—namely, petroleum hydrocarbons and methane. The method involves the delivery of atmospheric (ambient) air below and around a building foundation at rates sufficient to maintain aerobic conditions in the vadose zone that act as a “biobarrier” to VI. The technology can also enhance the remediation of certain shallow subsurface vapor sources. The method represents a cost-effective alternative to other petroleum VI mitigation and remediation technologies (e.g., soil vapor extraction (SVE) and sub-slab depressurization (SSD)) because the technology is applied in situ and does not require expensive vapor treatment or intrinsically safe equipment.

Similar to performance evaluation for VI mitigation strategies described above in Section 4.4, the effectiveness of using AVMB to address VI is reflected by indoor air concentrations of COCs (primarily petroleum hydrocarbons and methane) over time. Additionally, measurement of sub-slab vapor COC concentrations over time provides evidence that the AVMB system is effectively reducing petroleum hydrocarbon and methane COCs.

5 References and Acronyms

The ITRC VI Mitigation Training web page includes lists of acronyms, a full glossary, and combined references for the fact sheets. The user is encouraged to visit the ITRC VI Mitigation Training web page to access each fact sheet and supplementary information and the most up-to-date source of information on this topic.

Click here to view a PDF version of this Fact Sheet.