This ITRC Technology Information Sheet provides the general description of SVE as a remedial technology that can serve as VI mitigation. Included is an overview of SVE, as well as design considerations, a list of typical SVE components, conditions for applicability as a VI mitigation method, and advantages and disadvantages of applying SVE to mitigate VI. Cost considerations and a list of additional resources are provided. This Technology Information Sheet is intended to provide basic information that will enable the user to evaluate the applicability of SVE to support mitigating VI. |

Overview

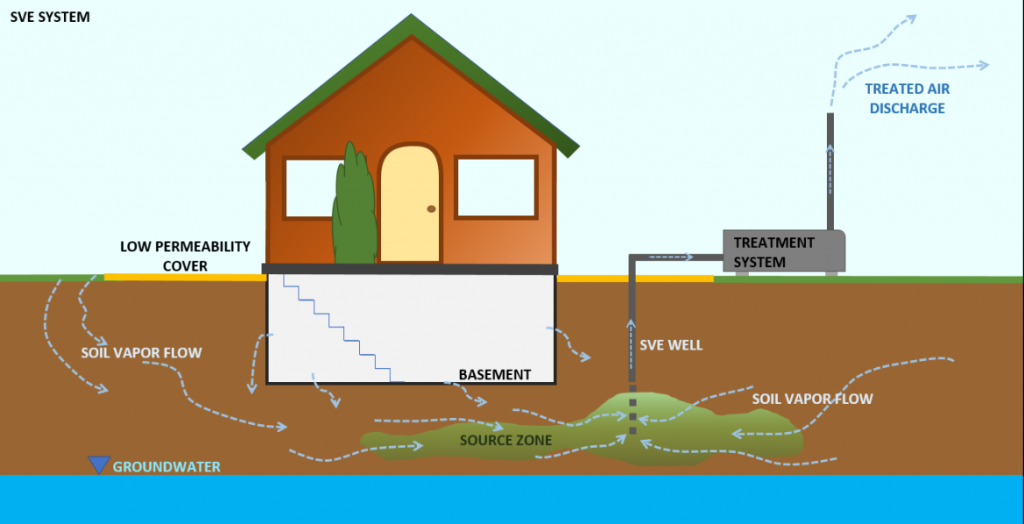

SVE is a remediation technology that is based on the extraction of soil vapor from the subsurface to reduce or eliminate a source of volatile organic compounds (VOCs) in the unsaturated zone. The soil vapor is extracted by creating negative pressure in the unsaturated zone by means of extraction wells or trenches connected to suction (Figure 1). This is similar in concept to sub-slab depressurization (SSD), and both technologies can provide means of mitigating VI into buildings. However, while VI mitigation is the main objective of SSD, SVE is concerned primarily with addressing the source, with the VI mitigation being a possible ancillary effect. During SVE, the VOCs in the unsaturated zone undergo volatilization from the source materials and are removed with the extracted soil vapor. The off-gas is typically treated before being discharged into the atmosphere in accordance with applicable federal, state, or local laws and regulations. SVE is applicable to sites impacted by VOCs where a sufficient thickness and permeability of the unsaturated zone are present to enable soil vapor extraction.

Source: L. Trozzolo, used with permission.

In the context of VI mitigation, an SVE system can prevent the migration of VOCs into a building from sources located both below and at certain distance from the structure. In the former case, the mitigation mechanism is the development of a negative pressure zone in the subsurface below the building, resulting in an outward air flow across the building floor. In the latter case, the SVE system might intercept the VOCs before they reach the building footprint.

Design Considerations

SVE systems are designed based on the findings of field investigations and a conceptual site model representative of site-specific conditions. Pilot testing is performed to establish the number and locations of the extraction wells/trenches and the vacuums applied. The system must be capable of developing sufficient venting rates to affect the VOC mass removal in a reasonable time frame (typically assumed to be between 1 and 5 years). Therefore, the primary indicator evaluated is the vapor flow rate in the subsurface, rather than the negative pressure. The testing also provides information on the need to install a surface cover to reduce the short-circuiting of the vapor flow through the surface, and the need to include air inlet wells/trenches to direct the flow and optimize venting. Furthermore, the VOC concentrations measured in the extracted air stream are used to evaluate the need for off-gas treatment and to design the treatment system. Many SVE systems require atmospheric discharge permitting in accordance with applicable federal, state, or local laws and regulations. Noise mitigation measures may also be necessary.

In the context of VI mitigation, the investigation should include an assessment of the SVE system’s effect on the indoor air quality. This may include pre- and postimplementation sampling of the indoor air for the target VOCs and monitoring of the pressure differential across the floor slab.

Components and Operation

A typical SVE system (Figure 1) consists of extraction facilities (wells or trenches) and mechanical/treatment equipment (conveyance piping, blower, vapor/liquid separator, liquid treatment or disposal, vapor treatment, instrumentation, and controls). A surface cover (e.g., building or cap) and air supply (inlet wells or trenches) may also be included. An SVE system requires regular maintenance and monitoring, which can constitute a large portion of the remediation costs. SVE system closure typically involves achieving the site-specific cleanup goals of soil quality. If used as a means of VI mitigation, additional closure requirements related to the indoor air quality may be necessary.

Applicability of SVE for VI Mitigation

SVE is directly applicable as a method of VI mitigation for relatively small sites, such as a single building, where rented mobile systems or repurposed systems from other sites can be deployed relatively quickly. SVE can also be effective as VI mitigation at larger sites. However, the permitting, design, and implementation time for larger sites is longer than the VI mitigation time frames typically required by regulatory agencies. Temporary VI mitigation may be needed until the SVE starts operating. Refer to the ITRC documents for the active, passive, and rapid response VI mitigation for information on possible temporary VI mitigation methods.

Advantages

The features of an SVE system are based on the requirement to accomplish the main objective of this technology, —source remediation. Compared to the dedicated VI mitigation systems, the advantages of SVE are:

- provides both remediation and exposure mitigation

- can result in complete removal of the source of the impacts to soil vapor, limiting the total time frame of the system operation (providing site closure, limiting long-term cost)

- can reduce or eliminate potential future liability and on-site or off-site contaminant impacts

- typically more robust than SSD (higher negative pressures in the subsurface)

- can be less intrusive to building occupants

- can be a suitable alternative when access is limited or denied

- by intercepting soil vapor migrating horizontally, it can provide VI mitigation for offsite sources

Limitations

The limitations of SVE systems include:

- typically higher short-term cost than dedicated VI mitigation methods

- permitting for off-gas discharge

- need for treatment of the off-gas and moisture in accordance with applicable federal, state, or local laws and regulations (increased long-term operation and maintenance costs)

- need for sampling and reporting

- greater likelihood for noise complaints

- feasible only at sites with granular and relatively permeable soils

Cost Considerations

An SVE system is designed to address the source of the VOCs in the unsaturated zone. The cost typically depends on the size and the logistics of the site, the nature of the subsurface, and the type of impacts. The added cost if SVE is also used as a means of VI mitigation is typically negligible. If comparing to the cost of a dedicated VI mitigation system, the entire life cycle costs should be included.

Occupant, Community, and Stakeholder Considerations

It is essential to develop and implement a site-specific community involvement plan that addresses, among other things, how to win trust and gain access to properties, communicate risk to potentially exposed individuals, and minimize the disruption of people’s lives and businesses. For more details see ITRC’s Public Outreach During Vapor Intrusion Mitigation Fact Sheet.

Resources

- US Army Corps of Engineers. 2002. Engineering and Design, Soil Vapor Extraction and Bioventing. EM 1110-1-4001. https://www.publications.usace.army.mil/Portals/76/Publications/EngineerManuals/EM_1110-1-4001.pdf

- USEPA, Office of Solid Waste & Emergency Response. 2012. A Citizen’s Guide to Soil Vapor Extraction and Air Sparging.542-F-12-018. https://www.epa.gov/sites/default/files/2015-04/documents/a_citizens_guide_to_soil_vapor_extraction_and_air_sparging.pdf

- Stewart, L, C. Lutes, R. Truesdale, B. Schumacher, J.H. Zimmerman, and R. Connell. 2020. Field Study of Soil Vapor Extraction for Reducing Off‐Site Vapor Intrusion. Groundwater Monitoring & Remediation 40(1):74-85.

- USEPA. 2018. Engineering Issue: Soil Vapor Extraction (SVE) Technology. EPA/600/R-18/053. https://cfpub.epa.gov/si/si_public_record_Report.cfm?dirEntryId=345171&Lab=NRMRL

Related Links:

For more information and useful links about VI pathways and mitigation technologies, go to http://www.itrcweb.org .

[email protected], 919-707-8279 Matthew Williams, Michigan Dept. of Environment, Great Lakes, and Energy [email protected], 517-881-8641 |

Click here to view a PDF version of this Tech Sheet.