This ITRC Technology Information Sheet describes a novel method for in situ vapor intrusion (VI) mitigation and remediation at sites with existing buildings situated above subsurface sources of VOCs that rapidly biodegrade aerobically—namely, petroleum hydrocarbons and methane. The method involves the delivery of atmospheric (ambient) air below and around a building foundation at rates sufficient to maintain aerobic conditions in the vadose zone that act as a “biobarrier” to VI. The technology can also enhance the remediation of certain shallow subsurface vapor sources. The method represents a safer, more sustainable, and cost-effective alternative to other petroleum VI mitigation and remediation technologies (e.g., soil vapor extraction (SVE) and sub-slab depressurization (SSD)) because the technology is applied in situ and does not require expensive vapor treatment or intrinsically safe equipment. This Technology Information Sheet provides basic information to assist the practitioner in potential AVMB application and decision making. |

Overview

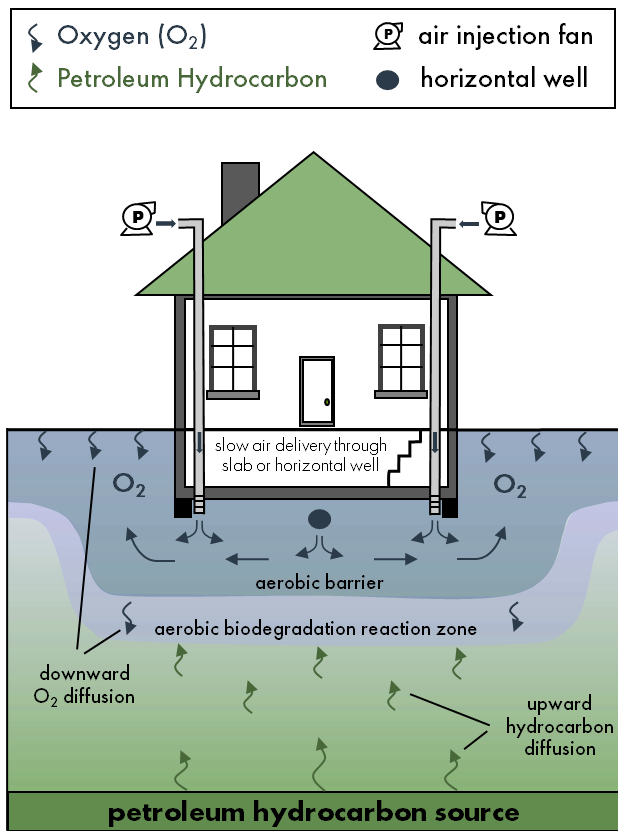

Aerobic vapor migration barrier (AVMB) is an in situ VI mitigation and remediation technology designed to aerobically biodegrade hydrocarbons in the vadose zone before they migrate to indoor air. The technology is primarily applicable for volatile organic compounds (VOCs), such as petroleum hydrocarbons (e.g., benzene, toluene, ethylbenzene, and xylenes (BTEX)) and methane, that tend to biodegrade rapidly under aerobic conditions at rates that exceed rates of gas migration by diffusion and advection (DeVaull, 2007). The technology involves the slow delivery of atmospheric (ambient) air containing 21% oxygen (O2) below and around existing building foundations at low rates via sub-slab vents, drain tiles, or horizontal wells (see Figure 1). The technology can also serve as a remediation technology at certain sites with shallow vapor sources. The technology represents a more cost-effective alternative to conventional petroleum VI mitigation and remediation methods because mitigation and remediation may be achieved in situ, thereby eliminating the need for expensive vapor treatment and intrinsically safe equipment. The technology is described in greater detail in (Luo et al., 2013).

Design Considerations

The aim of the AVMB is to create an atmospheric oxygen boundary condition between the contaminant source and building foundation sufficient to aerobically biodegrade petroleum hydrocarbon concentrations (and methane) below risk-based screening levels for VI. The air is delivered at a slow rate (e.g., 1–10 liters per minute) that is only sufficient to develop and maintain a 3- to 5-foot-thick aerobic biodegradation zone (defined by oxygen concentrations greater than 5% by volume) between the building foundation and the source of petroleum vapors in the subsurface. The air is not injected at pressures that would enhance potential short-term VI or displace vapors around the building foundation. An equation to estimate the minimum air injection rate is provided in (Luo et al., 2013). This airflow rate is approximately 10–1,000 times lower than airflow rates typically associated with typical 90-watt fans used for SSD or sub-slab ventilation (SSV) systems. The technology relies predominantly on molecular diffusion (concentration gradient–driven transport) rather than advection (pressure gradient–driven transport) for oxygen delivery and VI mitigation. Minimizing the formation of pressure gradients avoids the displacement of hydrocarbon vapors through and around building foundations that could potentially occur during the initial few days after system start-up. Key variables affecting the air injection rate include:

- the area of the building foundation

- total petroleum hydrocarbons (TPH), methane, or hydrocarbon-specific source vapor concentrations

- the oxygen concentration and depth below the foundation for which aerobic conditions are targeted

- the vertical separation distance between the hydrocarbon vapor source and the air injection point

- the effective diffusion coefficient of the soil around the injection point, which can either be estimated from theoretical relations or measured in situ (Johnson et al., 1998)

Components of AVMB Systems

Components of an AVMB system generally include:

- an air-injection fan that can generate air-flow rates in excess of 100 liters per minute at 20 pounds per square inch gauge

- a valve and flowmeter to regulate and measure airflow, respectively

- horizontal wells, drain tiles, or sub-slab vents for air injection

- a network of multilevel soil-gas monitoring points located adjacent to and beneath the building foundation for measuring concentrations of hydrocarbon vapors (TPH, including methane and/or specific hydrocarbons, such as benzene) and certain fixed gases (e.g., oxygen, carbon dioxide, methane, and nitrogen)

Optional equipment and measurements include:

- oxygen sensors to measure concentrations in real time and allow for automated and optimized ambient air injection

- the moisture content and total porosity of the soil around the injection point for estimating the effective diffusion coefficient, if not measured in situ

The equipment and materials needed for AVMB applications are reported in greater detail in Luo et al. (2013).

Applicability of AVMB for Vapor Intrusion Mitigation

AVMB systems are mainly applicable for existing buildings with petroleum hydrocarbon sources that are susceptible to aerobic biodegradation in the subsurface and sites where individual, discrete building VI mitigation is desired.

Advantages

AVMB systems are generally safer than typical SSD systems for petroleum VI mitigation because they do not require intrinsically safe equipment to process flammable hydrocarbon vapors drawn in from shallow light non-aqueous phase liquid (LNAPL) sources by SSD implementation. AVMB systems are also relatively more sustainable and cost-effective than conventional SVE, multiphase extraction (MPE), and SSD systems that require expensive vapor treatment. These advantages result largely because vapor mitigation and remediation take place in the subsurface rather than ex situ. In general, AVMB systems:

- do not require expensive vapor treatment and permitting, intrinsically safe equipment, or mechanisms to treat entrained formation/source water

- can be operated over shorter time periods relative to SSD and SSV systems, which do not remediate the vapor source

Limitations

Primary limitations of AVMB systems include:

- novelty of the technology (i.e., no widespread implementation)

- inability to effectively

- mitigate constituents that do not biodegrade rapidly under aerobic conditions (e.g., most chlorinated solvents) and shallow groundwater sources located within a foot of the building foundation

- remediate hydrocarbon sources located beyond 5–10 feet below the injection point or low-permeability soils

- need for specialized drill rigs and sufficient open space from the edge of the building foundation (e.g., ~20 feet) for horizontal well installations

- potential to damage under-foundation pipework (e.g., drains and other building penetrations) during horizontal well installation

Cost Considerations

Primary factors affecting the cost of an AVMB system are the size of the building foundation and diffusive properties of the soils located near the injection point. Installation costs are assumed to range between $10 and $100,000 depending on the building footprint and number of injection points. Annual operating costs are estimated to be about $1.75 at $0.1/kwh, or about 100 times less than those associated with conventional sub-slab ventilation systems.

Occupant, Community, and Stakeholder Considerations

The development and implementation of a site-specific community involvement plan that includes how to win trust and gain access to properties, communicate risk to potentially exposed individuals, and minimize the disruption of people’s lives and businesses is essential. For more details see the ITRC VI Public Outreach During Vapor Intrusion Mitigation Fact Sheet.

Related Links:

- DeVaull, G.E. 2007. Indoor vapor intrusion with oxygen-limited biodegradation for a subsurface gasoline source. Environ. Sci. & Technol. 41, 3241–3248.

- Johnson, P.C., Bruce, C, Johnson, R.L., and M.W. Kemblowski. 1998. In situ measurement of effective vapor-phase porous medium diffusion coefficients. Environ. Sci. Technol. 32, 3405−3409.

- Luo, H., Dahlen, P.R., Johnson, P.C., and T. Peargin. 2013. Proof-of-concept study of an aerobic vapor migration barrier beneath a building at a petroleum hydrocarbon-impacted site. Environ. Sci. Technol. 47, 1977-1984.

For more information and useful links about VI pathways and mitigation technologies, go to http://www.itrcweb.org .

[email protected], 919-707-8279 Matthew Williams, Michigan Dept. of Environment, Great Lakes, and Energy [email protected], 517-881-8641 |

Click here to view a PDF version of this Tech Sheet.